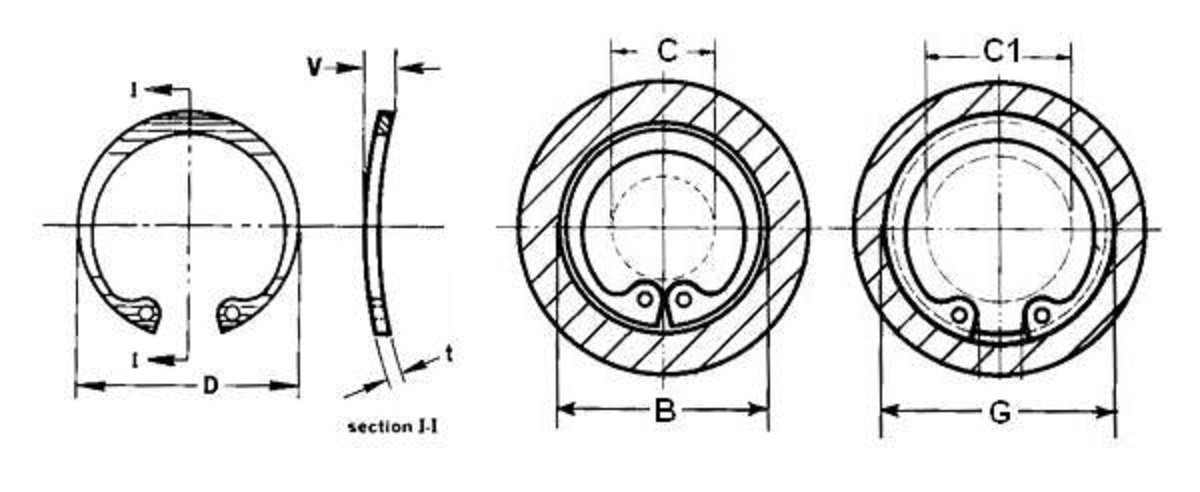

Snap rings, also known as retaining rings or circlips, are essential mechanical components widely used across industries for securing parts in place on shafts or within housings. Among the various types, the N-5001-62 Snap Ring is notable for its unique design and functionality, making it a popular choice in many applications. This article will explore the characteristics, applications, and benefits of the N-5001-62 Snap Ring. Along with installation and maintenance tips to ensure it performs effectively over time.

What is the N-5001-62 Snap Ring?

The N-5001-62 Snap Ring is a type of external retaining ring commonly used to hold components on a shaft. The “N-5001-62” part number signifies specific dimensions and specifications. Its design includes a circlip shape with a slight opening. Which allows the ring to expand slightly during installation and contract once in place, creating a firm hold.

One of the main features of the N-5001-62 Snap Ring is its ease of installation and removal. Thanks to its two small holes on each end. precision of its design and its sturdy construction make it a highly reliable component for securing parts without the need for additional fasteners or adhesives.

Key Applications of the N-5001-62 Snap Ring

The N-5001-62 Snap Ring is versatile and suitable for various industries, including automotive, aerospace, machinery manufacturing, and electronics. Its primary purpose is to secure components on a shaft or inside a housing, ensuring that they remain in position under various loads and operating conditions. Common applications include:

- Automotive Assemblies: In the automotive industry, snap rings like the N-5001-62 are used in transmission systems, gear assemblies, and drive shafts to secure bearings, gears, and other rotating parts.

- Machinery and Equipment: This snap ring is ideal for heavy machinery and industrial equipment, where it is used to hold components in place within shafts and housings, providing stability under high loads and stresses.

- Aerospace and Defense: The aerospace industry requires precision and reliability in component assemblies, making snap rings essential for securing delicate parts in tight spaces.

The N-5001-62’s durability, compact design, and adaptability make it an excellent choice for these high-stress, high-demand applications.

Benefits of Using the N-5001-62 Snap Ring

The N-5001-62 Snap Ring offers several advantages that contribute to its widespread use. Some of these benefits include:

- Reliability and Strength: Made from high-quality materials, the N-5001-62 Snap Ring is designed to withstand extreme stress and pressure. Making it suitable for heavy-duty applications.

- Space Efficiency: Unlike bulky fasteners, the snap ring is a compact component that takes up minimal space in an assembly.

- Cost-Effective Solution: The N-5001-62 Snap Ring eliminates the need for additional fasteners, adhesives, or complex locking mechanisms, reducing both material costs and installation time.

- Reduced Wear and Tear on Parts: Because it holds components securely in place, the snap ring minimizes the likelihood of parts moving or vibrating. Which reduces wear and prolongs the life of the entire assembly.

Installation Tips for the N-5001-62 Snap Ring

Proper installation of the N-5001-62 Snap Ring is essential for its performance and longevity. Here are some tips to ensure a secure and reliable fit:

- Choose the Right Tools: Snap ring pliers are necessary for proper installation. These pliers come in different designs (internal and external), so ensure you have the right type for the snap ring’s position (external in this case).

- Inspect the Groove: Before installation, inspect the groove on the shaft or housing where the snap ring will be placed. It should be free from debris and corrosion, as these can compromise the ring’s fit.

- Check the Orientation: Make sure the snap ring’s opening faces a direction where it won’t be exposed to extreme forces.

- Avoid Over-Expanding: Only expand the snap ring enough to fit it over the shaft. Over-expanding the ring can weaken its structure, reducing its ability to hold components securely.

Maintenance and Replacement Considerations

The N-5001-62 Snap Ring is durable, but like any mechanical component, it may eventually wear out due to repetitive stress. Regular maintenance is crucial to avoid potential failures. Inspect snap rings for signs of wear, deformation, or corrosion. If the snap ring shows signs of damage, it’s best to replace it promptly. As a compromised snap ring can lead to costly repairs or even damage to the entire assembly.

During maintenance, ensure the snap ring groove remains clean and free of contaminants. Proper lubrication can also reduce wear on both the ring and the groove, enhancing its lifespan.

Conclusion

The N-5001-62 Snap Ring is a versatile and efficient solution for securing components in a variety of industrial applications. Its robust design, combined with ease of installation and cost-effectiveness. Makes it an invaluable asset in automotive, machinery, aerospace, and electronics industries. By understanding its applications, benefits, and maintenance requirements, engineers and technicians can ensure the N-5001-62 Snap Ring performs reliably, providing stability and security to critical components.