Planetary gear systems, also known as epicyclic gears, are among the most efficient and versatile mechanisms used in modern engineering. Their unique design enables them to deliver high torque, compact size, and smooth operation. Among the most common configurations, the 3:1 reduction planetary gear system is particularly popular for its simplicity and wide range of applications. This article explores the design, functionality, and benefits of the 3:1 reduction planetary gear system.

What Is a Planetary Gear System?

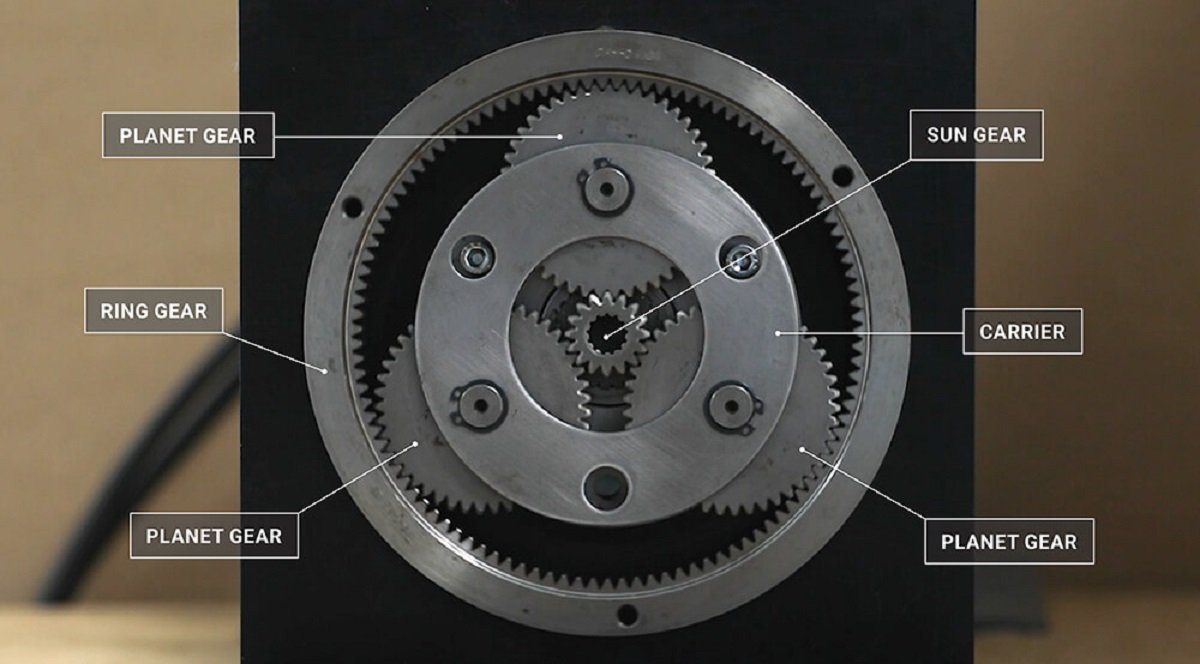

A planetary gear system consists of three primary components:

- Sun Gear: The central gear around which the other gears rotate.

- Planet Gears: Multiple gears that mesh with the sun gear and revolve around it.

- Ring Gear: An outer gear that encases the planet gears and meshes with their teeth.

The name “planetary gear” derives from its resemblance to a solar system, with the sun gear representing the sun and the planet gears orbiting around it within the ring gear.

How Does a 3:1 Reduction Work?

In a 3:1 reduction system, the input speed of the motor or drive is reduced to one-third of its original speed while increasing the torque proportionally. The gear ratio is determined by the relative number of teeth on the sun gear, the planet gears, and the ring gear.

For example:

- If the sun gear has 20 teeth and the ring gear has 60 teeth, the gear ratio is calculated as: Gear Ratio=1+Teeth on Ring GearTeeth on Sun Gear=1+6020=3:1\text{Gear Ratio} = 1 + \frac{\text{Teeth on Ring Gear}}{\text{Teeth on Sun Gear}} = 1 + \frac{60}{20} = 3:1

Benefits of a 3:1 Planetary Gear Reduction

1. Compact Design

One of the standout features of planetary gear systems is their compact size. A 3:1 reduction can achieve significant torque multiplication without requiring a bulky mechanism, making it ideal for applications with space constraints.

2. High Torque Output

Planetary gears evenly distribute the load among the planet gears, allowing for higher torque transmission compared to traditional gear systems. This makes the 3:1 reduction system suitable for demanding applications like robotics, industrial machinery, and automotive transmissions.

3. Efficiency

With minimal energy loss due to friction and heat, planetary gear systems boast efficiencies of over 95%. This high efficiency is crucial in energy-sensitive applications, such as electric vehicles and renewable energy systems.

4. Durability and Reliability

The load-sharing nature of planetary gears reduces wear and tear, extending the lifespan of the system. Additionally, their robust construction ensures reliable performance even under heavy loads and adverse conditions.

Applications of 3:1 Reduction Planetary Gears

The versatility of the 3:1 planetary gear system makes it a preferred choice in numerous industries, including:

1. Automotive Transmissions

Planetary gears are integral to automatic transmissions, where their compact size and high torque capabilities ensure smooth gear shifts and efficient power transfer.

2. Robotics and Automation

In robotics, precise control of motion and torque is essential. The 3:1 reduction system enables robots to move with precision and power, whether it’s for robotic arms, wheels, or actuators.

3. Aerospace

Aerospace applications demand lightweight and durable mechanisms. Planetary gear systems provide the necessary torque and reliability for components like aircraft flaps, satellite systems, and drone propellers.

4. Renewable Energy

In wind turbines and solar tracking systems, planetary gears help manage speed and torque efficiently, ensuring optimal energy conversion and system performance.

5. Industrial Machinery

From conveyor belts to printing presses, planetary gears are used in various industrial machines that require consistent torque and reliable operation.

Limitations of Planetary Gears

While planetary gear systems offer numerous advantages, they are not without limitations. These include:

- Complex Manufacturing: The intricate design of planetary gears requires precision engineering, which can make them costlier to produce.

- Noise at High Speeds: In high-speed applications, planetary gears may generate more noise compared to other gear systems.

Conclusion

The 3:1 planetary gear reduction system exemplifies engineering ingenuity, providing a blend of efficiency, compactness, and reliability. Its wide range of applications, from robotics to renewable energy, demonstrates its adaptability and importance in modern technology.

Understanding the fundamentals of planetary gears can help engineers and designers make informed decisions when selecting gear systems for specific applications. Whether in high-torque scenarios or space-limited designs, the 3:1 reduction system continues to be a cornerstone of mechanical innovation.